ABOUT THE CLIENT

SALMON RESEARCH FACILITY IN NEW ZEALAND

Cawthron Institute is New Zealand’s largest independent science organization, offering a broad spectrum of services to help protect the environment and support the sustainable development of primary industries. Cawthron is a diverse organization employing more than 275 scientists, laboratory technicians, researchers, and specialist staff from 26 countries. Cawthron’s scientists are specialists in aquaculture research, marine and freshwater resource management, food safety and quality, algal technologies, biosecurity, and analytical testing. Its ground-breaking science is supported by substantial testing and research laboratories, state-of-the-art technology, and a purpose-built aquaculture park.

WHAT THE CLIENT NEEDED

Chinook Salmon

Chinook salmon species are the largest in the Pacific salmon genus and is often referred to as King Salmon. It has gained popularity in the market due to the high amount of omega-3 fatty acids found in its flesh. However, fishing alone is not capable of meeting the demand and because its numbers have dangerously declined in the wilderness, the fish producers were pushed to find another way to meet it. Today, the largest farmed Chinook Salmon producer in the world is New Zealand as it accounts for about half of the global production. Fortunately, New Zealand is putting great emphasis on keeping its aquaculture industry as environmentally friendly as possible. As a result of this, they have been recognized as the most sustainable in the world by Global Aquaculture Performance Index in 2011.

The Chinook Salmon Research Facility

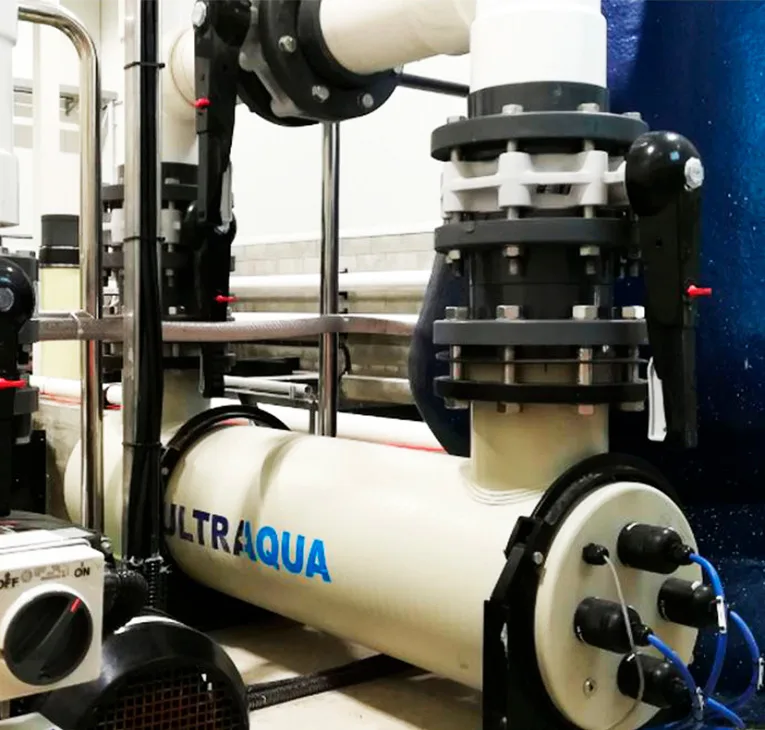

Together with Fresh By Design, ULTRAAQUA UV installed its UV systems in the Chinook Salmon research facilities for the latest Cawthron Institute project – Finfish Research Centre (FRC). The FRC facility has 6 individual systems – four large feed trial systems and two smaller physiology systems that can be run on either freshwater or seawater. The facility was designed to conduct Chinook Salmon research from fry through to harvest size. However, it can also be used for multiple fish species due to the flexibility of its design. Each of the individual systems has 8000L or 2500L liter bespoke fiberglass tanks with dual drains and swirl separators for waste collection and analysis.